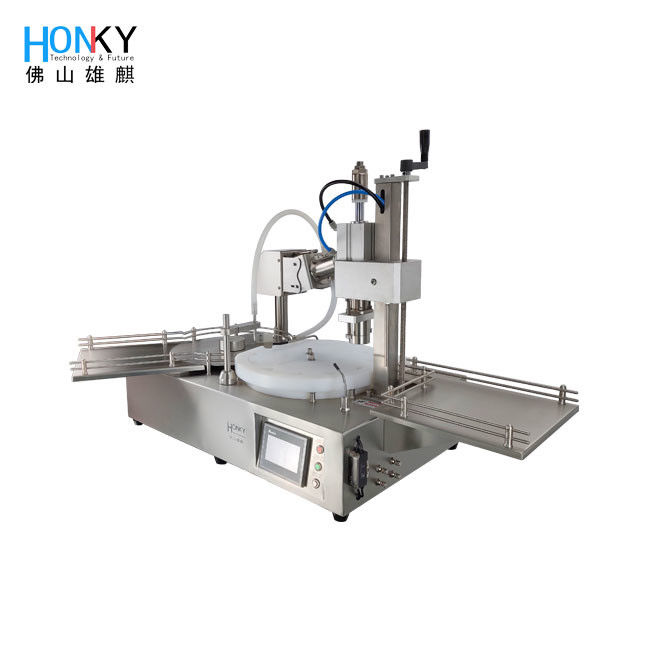

10ml Vial Desktop Type Ceramic Pump Filling Machine

Professional desktop filling and crimping machine designed for liquid dressing packaging in 10ml glass vials. Features precision ceramic pump technology for exceptional accuracy and consistency.

Key Features

- GMP workshop compliant - suitable for clean bench operation

- Self-developed intelligent operating system for easy operation

- XQX2 ceramic pump with high measuring accuracy and repeat consistency

- 304 stainless steel construction for corrosion resistance

- Special material coating hardening treatment for long service life

- Quick mold installation with easy bottle type changeover

- German sensors for no-fill without bottle and no-rivet without lid functions

Technical Specifications

| Model |

XQGM-30A |

| Filling Range |

0.2-6ml | 1-12ml | 2-25ml |

| Filling Accuracy |

≤0.5% |

| Sealing Diameter |

φ13mm / φ15mm / φ20mm |

| Manufacturing Speed |

12-22 PCS/min |

| Power |

AC 220V 50-60Hz 600W |

| Air Pressure |

0.4-0.5Mpa |

| Host Machine Size |

1230*780*600(mm) |

Machine Display

This equipment has been tested to meet the requirements of GMP certification.

The separation part adopts high purity ceramic pump, which controls the injection volume of each lap by adjusting the angle of the pump head, and has extremely high measuring accuracy and repeated consistency.

Fully desktop design to make operation easy.

Why Choose HonkyTech?

Rich Experience

Skilled engineering staff with many years of experience in the precision-filling industry.

Quality Assurance

Strict quality control system with CE approval and ROHS Certificate.

In Stock

We maintain stock of ceramic pump parts, electronic components, and filling machine spare parts for immediate delivery.

Mature Technology

Numerous in-house service technicians and engineers provide comprehensive technical support.

Frequently Asked Questions

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine comes with a 1-year warranty. We offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We provide user manuals and videos for installing, debugging, and operating the machine.

Q: What info will be needed to confirm machine models?

A: 1. The material status

2. Filling range

3. Manufacturing speed

4. Requirements for the production process

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!