30ml Aromatherapy Oil Liquid Filling Capping Machine - Full Automatic for Daily Chemical

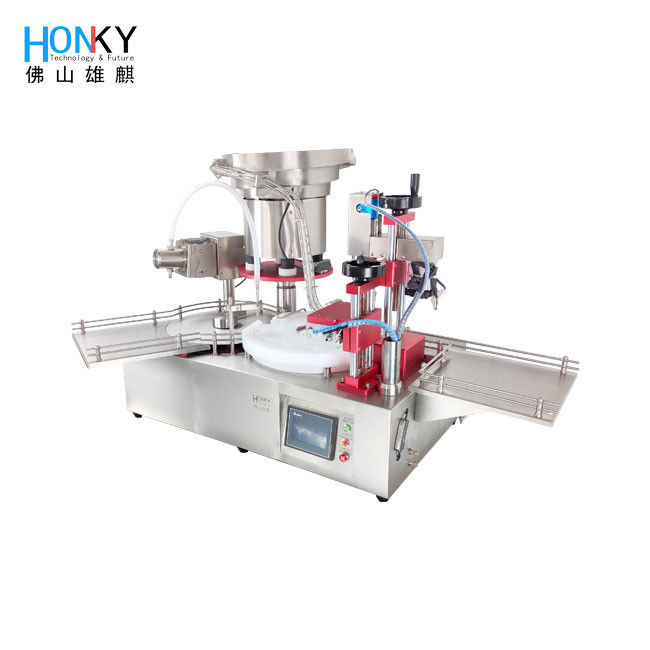

The Desktop Full Automatic 30ml Aromatherapy Oil Liquid Filling Capping Machine with Ceramic Piston Pump is specifically designed for daily chemical applications, offering precision filling and capping for reagent bottles.

Product Characteristics

- Fully automatic desktop design for filling and capping operations

- High-precision ceramic pump ensures accurate filling

- 304 stainless steel construction for easy cleaning and durability

- Production capacity up to 1800 bottles per hour

- Ideal for laboratory small batch production

- Automated operation reduces labor requirements

Technical Specifications

| Parameter |

Specification |

| Target Products |

Diluent |

| Manufacturing Speed |

20 PCS / minute |

| Power |

AC 220V 50-60Hz / 1kw |

| Air Range |

0.5-0.7Mpa |

Product Features

Compact design integrates filling, cap loading, and capping functions in one efficient workspace.

About HonkyTech

Foshan Xiongqi Intelligent Technology Co., Ltd (HONKY) is a leading manufacturer of comprehensive fluid filling solutions. Our product range includes ceramic pumps, ceramic pump filling line series, spare parts, filling equipment, and ODM filling solutions. Our products are renowned for their quality, reliability, and operational efficiency.

Frequently Asked Questions

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we offer both OEM services and technical support. We welcome distributors to establish OEM business relationships.

Q: How about the after-sales service?

A: All machines include a 1-year warranty. We provide lifetime after-sales service and ongoing technical support.

Q: What are your Installation Services?

A: Installation support is included with all new machine purchases. We provide comprehensive user manuals, instructional videos, and technical guidance for installation, debugging, and optimal machine operation.

Q: What info will be needed to confirm machine models?

A: The following information is required to determine the appropriate machine model:

- Material characteristics and properties

- Required filling range and volume

- Desired manufacturing speed

- Specific production process requirements

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!