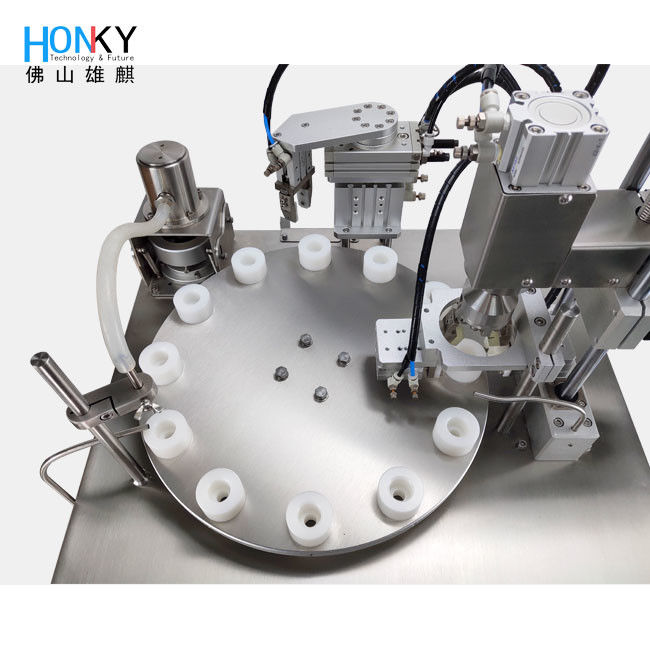

Desktop Bio Reagent Tube Small Volume Filling and Capping Machine

Advanced desktop filling and capping system designed for precision small-volume reagent applications with servo-controlled capping technology.

Key Features

- Intelligent Touch Control: User-friendly HMI touchscreen interface with programmable recipes

- Precision Dosing System: High-purity ceramic metering pump with ±0.5% accuracy and adjustable pump head rotation angle

- Excellent Repeatability: CV≤1.0% for consistent performance

- Hygienic Construction: 304 stainless steel housing with desktop design

- Advanced Capping Mechanism: Servo-controlled torque capping system ensures proper seal integrity without container damage

- Quick-Change Tooling: Modular bottle mold design enables <3 minute format changeover

- Wide Compatibility: Works with various container shapes (20-500ml)

- Smart Sensor System: German-made photoelectric sensors ensure no-fill without bottle detection and no-cap without lid detection

- Customizable Options: Optional plug/cover attachment modules and customized production speed (up to 60 bottles/min)

- Reliable Pneumatics: Taiwan-brand pneumatic components (AirTAC/SMC equivalent)

Technical Specifications

| Model |

XQZGX-12S |

| Pump Type |

Ceramic pump |

| Filling Accuracy |

≦±0.5% |

| Filling Range |

0.6-6ml |

| Manufacturing Speed |

25-30 PCS / minute |

| Power |

AC 220V 50-60Hz 550W |

| Air Pressure |

0.4-0.6Mpa |

| Machine Size |

710*660*670mm (Main machine roughly) |

Product Overview

This equipment has been tested to meet the requirements of GMP certification.

Applications

- Precision quantitative loading and dilution in pharmaceutical, food, chemical, and cosmetic industries

- Pre-chromatography preparation, pharmaceutical QC and R&D, environmental monitoring

- Mineral and blood analysis, forensic identification

- Precise quantitative loading and dilution of blood, biological reagents, oral agents, injections, advanced cosmetics, flavors, and fungicides

The capping part adopts SERVO torsional screwing to ensure the tightness and no-damaging of the lid.

The separation part adopts high purity ceramic pump, which controls the injection volume of each lap by adjusting the angle of the pump head, and has extremely high measuring accuracy and repeated consistency.

Fully desktop design to make operation easily.

Frequently Asked Questions

Do you offer OEM services, I am a distributor from overseas?

Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

How about the after-sales service?

The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

What are your Installation Services?

Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

What info will be needed to confirm machine models?

- The material status

- Filling range

- Manufacturing speed

- Requirements for the production process

About HonkyTech

Foshan Xiongqi Intelligent Technology Co., Ltd (HONKY) is a leading manufacturer of all kinds of fluid filling solutions. The main products contain the ceramic pump, ceramic pump filling line series, ceramic pump spare parts or filling equipment, filling solution ODM, etc. Our products have a good reputation for quality, reliability, and efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!