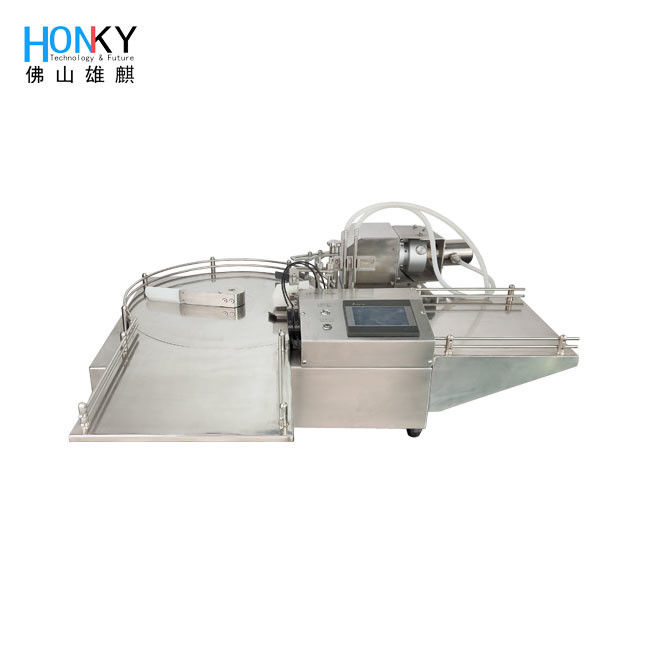

Ceramic Pump 5ml Essential Oil Bottle Filling Machine

High-Speed Desktop Filling Solution

The XQZPG dual-channel ceramic pump filling machine is specifically engineered for precision filling of small round bottles in the cosmetic industry. With a capacity of 4,000 bottles per hour, this compact desktop unit delivers exceptional accuracy and efficiency.

Technical Specifications

| Model |

XQZPG-2B Double Channel |

| Pump Head |

High Purity Ceramics |

| Filling Accuracy |

≤ ±0.25% |

| Filling Range |

0.5-2ml | 1.5-5ml | 3-10ml | 2-25ml |

| Bottle Diameter |

12-78mm |

| Manufacturing Speed |

40-80 PCS/min |

| Host Machine Size |

1130×430×240(mm) |

| Power |

AC 220V 50-60Hz 650W |

Key Features

- GMP certified equipment with intelligent operating system

- High-purity ceramic pump for precise liquid control

- 304 stainless steel construction with desktop design

- Optimized for stable bottle shapes and rapid bottle changeover

- Modbus 485 communication protocol support

- German sensor technology for no-fill, no-bottle functionality

Machine Overview

Space-saving desktop design reduces floor space requirements and simplifies operation.

Automatic dual-channel bottle loading with multi-head filling capability for various stable products.

Constructed from durable stainless steel 304 with customizable dimensions to meet specific customer requirements.

Proprietary precision ceramic pump technology delivers repeatable accuracy within ±0.3%.

Application Areas

- Cosmetic product packaging

- Pharmaceutical and bio-reagent product packaging

- Laboratory liquid dispensing

- Lithium battery liquid dispensing

- Various material filling applications

Frequently Asked Questions

Do you offer OEM services for overseas distributors?

Yes, we provide comprehensive OEM services and technical support to facilitate your OEM business operations.

What is included in your after-sales service?

All machines include a 1-year warranty with lifetime after-sales service and technical support.

What installation services do you provide?

Installation services are included with all new machine purchases. We supply detailed user manuals and instructional videos covering installation, debugging, and machine operation.

What information is needed to confirm machine models?

To determine the appropriate machine model, we require: material status, filling range specifications, manufacturing speed requirements, and specific production process requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!