Reagent 0.2ml Liquid Filling And Capping Machine With Double Head

Reagent 550W Liquid Filling And Capping Machine With Double Head

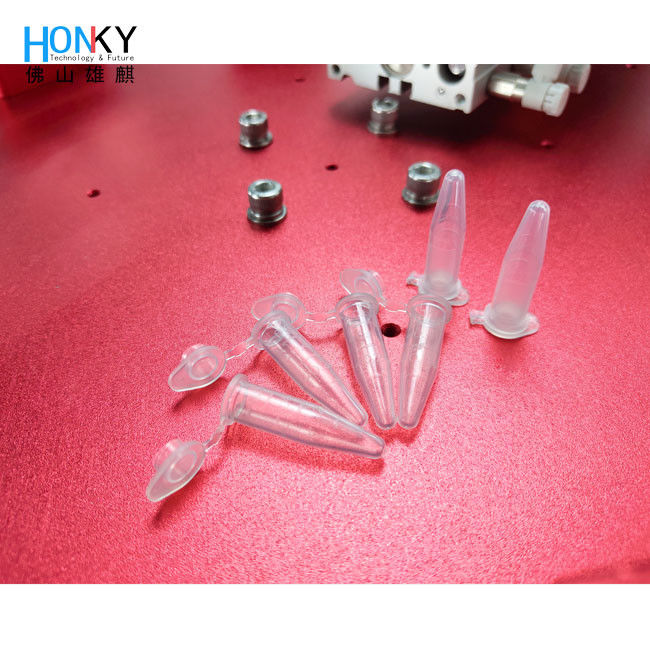

2400BPH Centrifuge Tube Volumetric Liquid Filling And Capping Machine With Ceramic Pump For Biological Reagents

Product Characteristics

The XQLXG-2S features a semi-automatic desktop filling and capping design, specifically engineered for centrifuge tubes. Equipped with a high-precision ceramic pump for exceptional filling accuracy, this machine is constructed from 304 stainless steel for easy cleaning. With a production capacity of up to 3000 bottles per hour, it's ideal for laboratory small-batch production. The specialized cap pressing mechanism ensures minimal cap damage.

Technical Specifications

| Model |

XQLXG-2S |

| Pump Type |

Ceramic Pump |

| Filling Accuracy |

≤±0.5% |

| Filling Range |

0.2-1.5ml |

| Manufacturing Speed |

40 PCS / minute |

| Power |

AC 220V 50-60Hz 550W |

| Air Pressure |

0.4-0.6Mpa |

| Machine Size |

710*660*670mm (Main machine roughly) |

Machine Features

This equipment has been tested to meet the requirements of GMP certification.

The separation system utilizes a high-purity ceramic pump, controlling injection volume per cycle by adjusting the pump head angle, delivering exceptional measuring accuracy and repeatable consistency.

Compact desktop design ensures straightforward operation and space efficiency.

Ceramic Pump Advantages

- Low Friction, Extended Service Life

- Exceptional Wear Resistance

- Superior Corrosion Resistance

- Enhanced Anti-Galling Surface Properties

Application Areas

- ODM and OEM Product Design

- Automatic Manufacturing Line Design

- Cosmetic Product Packaging

- Pharmaceutical and Bio-reagent Product Packaging

- Laboratory Liquid Dispensing

- Lithium Battery Liquid Dispensing

- Ceramic Pump and Component Design

- Other Material Filling Applications

Frequently Asked Questions

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we provide both OEM services and technical support. We welcome distributors to establish OEM partnerships.

Q: How about the after-sales service?

A: The machine includes a 1-year warranty with lifetime after-sales service and technical support.

Q: What are your Installation Services?

A: Installation support is included with all new machine purchases. We provide comprehensive user manuals and instructional videos covering installation, debugging, and machine operation.

Q: What info will be needed to confirm machine models?

A: Required information includes: 1. Material characteristics, 2. Filling range requirements, 3. Production speed requirements, 4. Specific process requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!