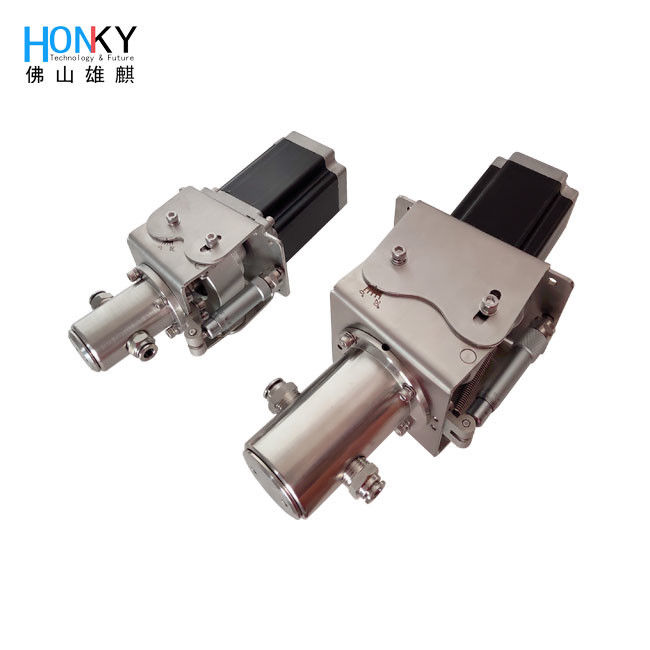

SS316L Ceramic Filling Pump

High Precision Ceramic Filling Pump Integration For Liquid Dispensing Filling Machine Accessory

The rotary ceramic plunger pump assembly is a plunger-type precision metering pump used for metering, filling or quantitatively filling chemical liquids and high-purity liquids. During the rotation of the plunger, Based on the adjustable pump head angle, the axial linear motion is generated to realize the precise adjustment of the stroke to control the input and output.

Features:

1. The metal part of the contact material is made of 316 stainless steel, the pump body has better corrosion resistance, and the operation of the pump will not produce trace impurities to pollute the liquid. Detachable pump head plunger group

Parts for cleaning and maintenance.

2. This series of metering pumps have very high metering accuracy and repeat consistency, and the accuracy is better than plus or minus five thousandths.

3. The X1 series is based on the lateral differential angle, and the adjustment is more sensitive. The X2 series is the most widely used and has a simple structure.

Application:

It can be used for matching and modification of the filling part of the packaging machine. Suitable for filling electrolyte, medicine, biochemical reagent, chemical liquid, essential oil, essence, lotion, perfume, finger

Homogeneous liquid materials with medium and low viscosity such as nail polish.

Parameter

| Item No. |

-3 |

-6 |

-9 |

-12 |

-15 |

-18 |

-21 |

-24 |

-27 |

| Pump Material |

Ceramic parts: high purity alumina(Al2O3), zirconia(ZrO2), silicon carbide(SiC), etc |

Metal part: 316L stainless steel |

| Filling Range |

4-80ul |

10-140ul |

20-240ul |

50-700ul |

0.2-1.5ml |

0.2-2.9ml |

0.6-6ml |

1-12ml |

2-25ml |

| Bore Diameter |

Φ4 |

Φ5 |

Φ7 |

Φ10 |

Φ13 |

Φ15 |

Φ22 |

Φ25 |

Φ36 |

RPM |

450 |

350 |

300 |

250 |

200 |

| Accuracy |

Better than ±0.5% |

| Motor Type |

2 phase 4 line No.42 |

2 phase 4 line No.57 |

2 phase 4 line No.86 |

| Power Supply |

AC220V 50/60Hz (110V can be customized) |

| Power Rate |

75w |

75w |

75w |

150w |

150w |

150w |

240w |

240w |

240w |

Product display

Application area

1. ODM and OEM products design;

2. Automatic manufacturing line design;

3. Cosmetic product packing;

4. Pharmaceutical and bio-reagent product packing;

5. Laboratory Liquid dispensing;

6. Lithium Battery Liquid dispensing;

7. Ceramic pump and ceramic pump part design;

8. Other area's material filling;

Why choose HonkyTech?

Rich Experience

There is skilled engineering staff with many years of experience, many of them have been engaging in this precision filling industry for many years.

Quality Assurance

With a strict and effective quality control system, our products are CE approved, and we have ROHS Certificate.

In Stock

We keep stock of ceramic pump parts, electronic components, filling machine spare parts, etc. ready for immediate delivery.

Mature Technology

With numerous in-house service technicians and engineers, HONKY is ready to assist when you need technical support.

About HonkyTech

Foshan Xiongqi Intelligent Technology Co., Ltd(HONKY) is a leading manufacturer of all kinds of fluid filling solutions. The main products contain the ceramic pump, ceramic pump filling line series, ceramic pump spare parts or filling equipment, filling solution ODM, etc. Our products have a good reputation for quality, reliability, and efficiency.

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!