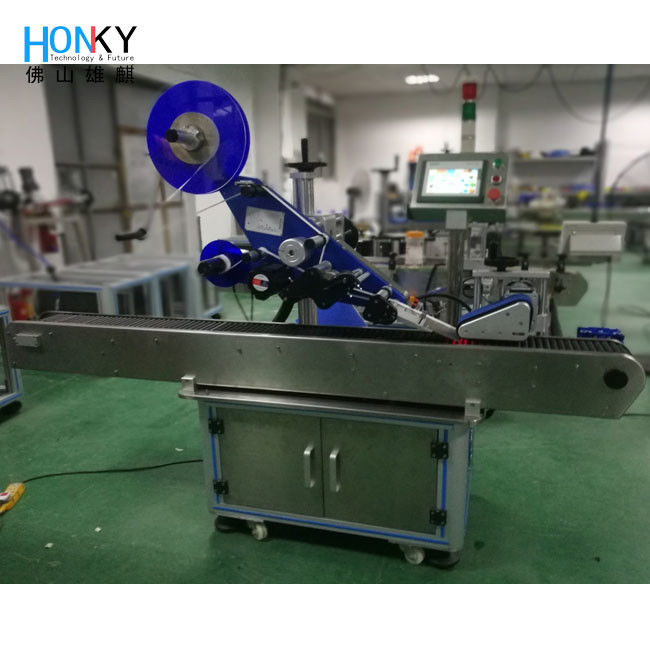

SUS304 3000BPH Filling Packing Machine Test Kit Labeling

Test Kit 3000BPH Horizontal Labeling Machine Automatic Labeling Machine For Filling Line. This high-speed labeling system is designed for efficient integration into production lines.

Key Features

- PLC control system for easy operation and reliability

- Main body constructed from durable SUS304 stainless steel

- Utilizes premium components from Japanese, German, American, Korean, and Taiwanese brands

- Optional integration with printers, coders, and conveyor systems

Application Scope

Suitable for automatic labeling of cylindrical packaging containers in pharmaceutical, cosmetic, personal care, and food industries.

Technical Specifications

| Model |

XQTB-80R |

| Bottle Size |

Φ20-50mm |

| Labeling Speed |

100ppm |

| Label Roll Inner Diameter |

Φ75mm |

| Labeling Precision |

≤ ±0.8mm |

| Host Machine Size |

2000*900*1400 mm |

| Power Supply |

AC220V 50/60Hz 750W |

Product Display

Why Choose HonkyTech?

Rich Experience

Our skilled engineering team brings years of expertise in precision filling industry applications.

Quality Assurance

All products meet CE certification standards and include ROHS compliance certification.

In Stock Availability

We maintain inventory of ceramic pump parts, electronic components, and filling machine spare parts for immediate delivery.

Mature Technology

With numerous in-house service technicians and engineers, we provide comprehensive technical support.

Frequently Asked Questions

Q: Do you offer OEM services for overseas distributors?

A: Yes, we provide both OEM services and technical support. We welcome distributors to establish OEM partnerships.

Q: What is included in your after-sales service?

A: All machines include a 1-year warranty with lifetime after-sales service and technical support.

Q: What installation services do you provide?

A: Installation support is available with all new machine purchases. We provide comprehensive user manuals, instructional videos, and technical guidance for installation, debugging, and operation.

Q: What information is needed to confirm machine models?

A: We require details about material status, filling range requirements, manufacturing speed specifications, and specific production process requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!