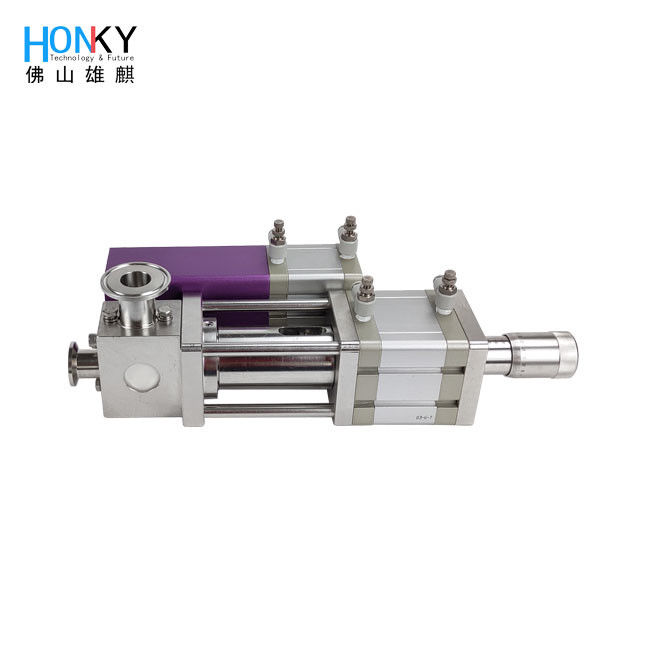

AutoAutomatic High Precision Pneumatic Pump Paste Filling Pump System With Ceramic Plunger For Biochemical Reagent Fillingmatic High Precision Pneumatic Pump Paste Filling Pump System With Ceramic Plunger For Biochemical Reagent Filling

The ceramic plunger pneumatic pump assembly adopts a precision ceramic plunger design, which is suitable for the quantitative infusion of medium and high viscosity liquids, creams, and creams (1000-100,000CPS) and materials containing certain particles.

Features of Paste Filling Pump System:

1. The tail screw fine adjustment structure makes the pump have high metering accuracy and repeat consistency, and the accuracy is better than ±0.5%.

2. The metal part of the contact material is made of 316L stainless steel, which has better corrosion resistance.

3. The pump body is connected in a quick-disassembly mode, which is convenient for disassembly, assembly, and cleaning, and meets the cleaning requirements of food hygiene standards.

Application of Paste Filling Pump System:

It can be used for the matching and transformation of the filling part of the packaging machine. It is very suitable for filling cream, honey, electrolyte, medicinal solution, biochemical reagent, chemical liquid, essential oil, essence, lotion, perfume, nail polish, and other medium and high viscosity homogeneous liquid materials.

Parameter of Paste Filling Pump System

| Model |

XQHB-10 |

XQHB-20 |

XQHB-50 |

|

| Pump head |

High purity ceramics |

| Filling accuracy |

≦±0.5% |

| Filling range |

1-12ml |

2-25ml |

5-50ml |

|

| Manufacturing speed |

0-40 Bottle/min |

| Size of the pump |

250*150*400 cm |

| Power |

Full air driven |

| Air pressure |

0.4-0.6Mpa |

Product display of Paste Filling Pump System

Advantages for using the ceramic:

1. Low Friction, Increased Packing Life

2. Extreme Wear Resistance

3. Increased Corrosion Resistance

4. Improved Anti-Galling Surface

About HonkyTech

Foshan Xiongqi Intelligent Technology Co., Ltd(HONKY) is a leading manufacturer of all kinds of fluid filling solutions. The main products contain the ceramic pump, ceramic pump filling line series, ceramic pump spare parts or filling equipment, filling solution ODM, etc. Our products have a good reputation for quality, reliability, and efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!