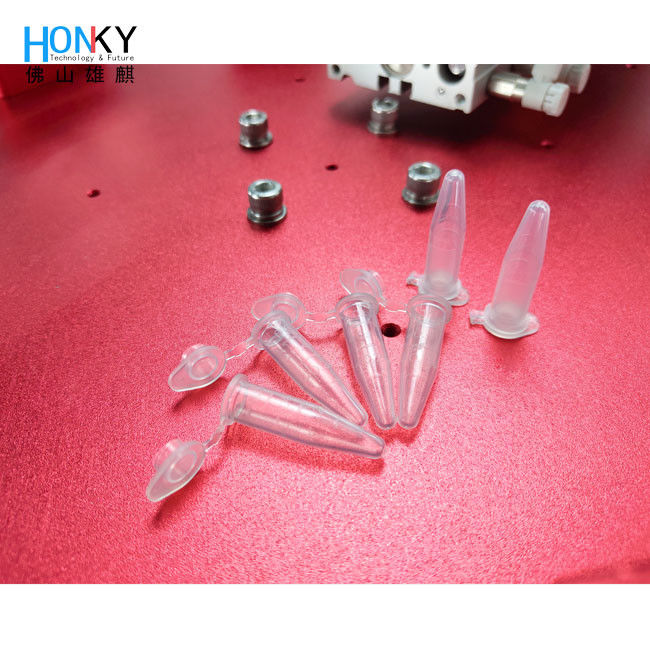

Bio-Reagent Centrifuge Tube Filling and Capping Machine

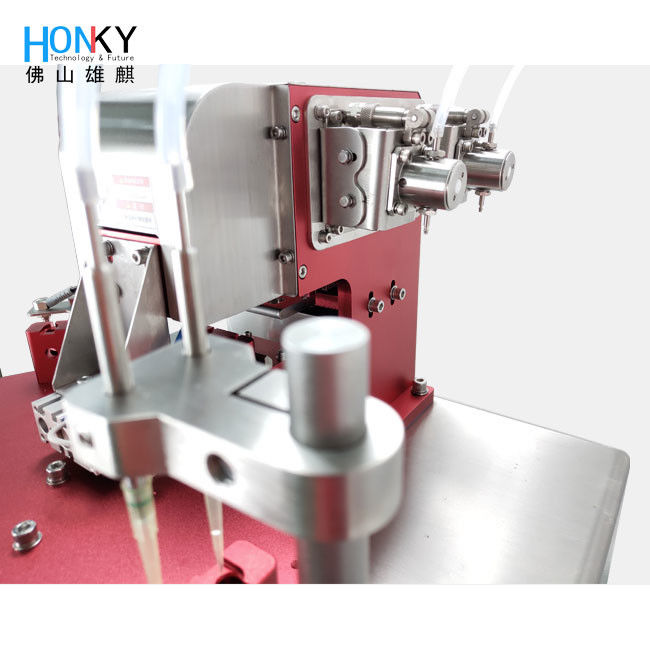

Desktop semi-automatic filling and capping machine designed specifically for bio-reagent centrifuge tubes, featuring high-precision ceramic pump technology and 304 stainless steel construction.

Key Features

- Semi-automatic desktop design for centrifuge tube filling and cap pressing

- High-precision ceramic pump ensures exceptional filling accuracy

- 304 stainless steel construction for easy cleaning and durability

- Production capacity up to 52 pieces per minute for batch processing

- Specialized cap pressing mechanism minimizes damage rate

Technical Specifications

| Model |

XQLXG-2S |

| Pump Type |

Ceramic pump |

| Filling Accuracy |

≤±0.5% |

| Filling Range |

0.2-1.5ml |

| Production Speed |

40-52 PCS/minute |

| Power |

AC 220V 50-60Hz 550W |

| Air Pressure |

0.4-0.6Mpa |

| Machine Dimensions |

710*660*670mm (Main machine) |

Product Overview

This equipment has been tested to meet the requirements of GMP certification.

The separation part utilizes high-purity ceramic pump technology, controlling injection volume per rotation by adjusting pump head angle, delivering exceptional measuring accuracy and repeatable consistency.

Fully desktop design ensures easy operation and space efficiency.

About HonkyTech

Foshan Xiongqi Intelligent Technology Co., Ltd (HONKY) is a leading manufacturer of comprehensive fluid filling solutions. Our product portfolio includes ceramic pumps, ceramic pump filling line series, spare parts, filling equipment ODM services, and more. Our products are renowned for their quality, reliability, and operational efficiency.

Frequently Asked Questions

Q: Do you offer OEM services for overseas distributors?

A: Yes, we provide both OEM services and comprehensive technical support. We welcome distributors to establish OEM partnerships.

Q: What after-sales services do you provide?

A: All machines include a 1-year warranty with lifetime after-sales service and technical support.

Q: What installation services are available?

A: Installation support is included with all new machine purchases. We provide detailed user manuals, instructional videos, and technical guidance for installation, debugging, and optimal machine operation.

Q: What information is needed to confirm machine models?

A: Please provide: 1. Material specifications, 2. Required filling range, 3. Desired production speed, 4. Specific process requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!