Desktop Automatic Vial Filling Capping Machine - 25BPM

Automatic Vial Filling & Capping Machine with production speed of 25 bottles per minute and high precision filling pump in a compact desktop design.

Key Features

- GMP certified equipment meeting industry standards

- Intelligent operating system for easy control

- High purity ceramic pump for precise volume control

- 304 stainless steel construction with desktop structure

- Special material coating on riveting parts for extended service life

- Quick mold-based installation with easy bottle type changeover

- German sensors for no-fill without bottle and no-cap without lid detection

- Automatic plug and cap loading for full automation

Technical Specifications

| Model |

XQGM-30B |

| Filling Range |

0.2-6ml | 1-12ml | 2-25ml |

| Filling Accuracy |

≤0.5% |

| Sealing Diameter |

φ13mm / φ15mm / φ20mm |

| Production Speed |

25 PCS/min |

| Power |

AC 220V 50-60Hz 1500W |

| Air Pressure |

0.4-0.5Mpa |

| Machine Dimensions |

1230×800×750(mm) |

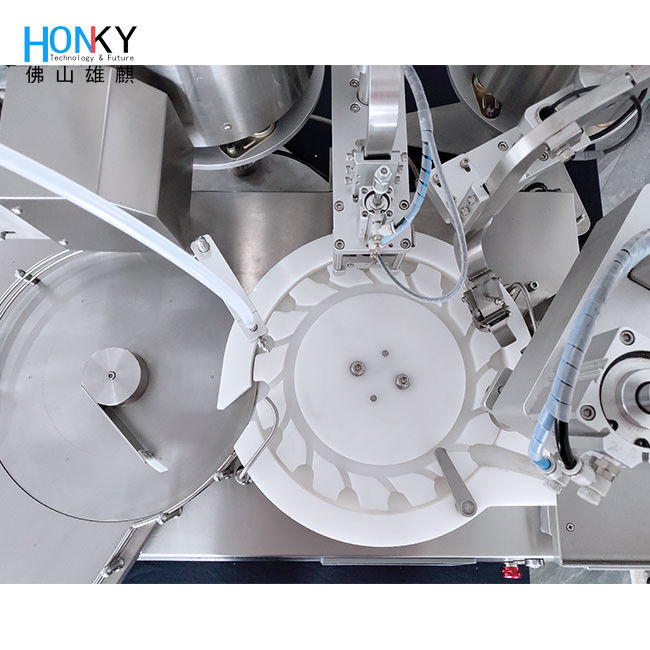

Product Gallery

GMP certified equipment meeting pharmaceutical industry standards

High purity ceramic pump ensures precise volume control with excellent measuring accuracy and repeatability

Fully desktop design for easy operation and space efficiency

About HonkyTech

Foshan Xiongqi Intelligent Technology Co., Ltd (HONKY) is a leading manufacturer of fluid filling solutions. Our product range includes ceramic pumps, ceramic pump filling line series, spare parts, filling equipment ODM, and custom filling solutions. Our products are renowned for their quality, reliability, and operational efficiency.

Frequently Asked Questions

Q: Do you offer OEM services for overseas distributors?

A: Yes, we provide both OEM services and technical support. We welcome distributors to start OEM business partnerships.

Q: What is included in your after-sales service?

A: All machines come with a 1-year warranty, plus lifetime after-sales service and technical support.

Q: What installation services do you provide?

A: Installation support is included with all new machine purchases. We provide comprehensive user manuals, instructional videos, and technical support for installation, debugging, and operation.

Q: What information is needed to confirm machine models?

A: We require the following details: material specifications, filling range requirements, desired production speed, and specific production process requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!