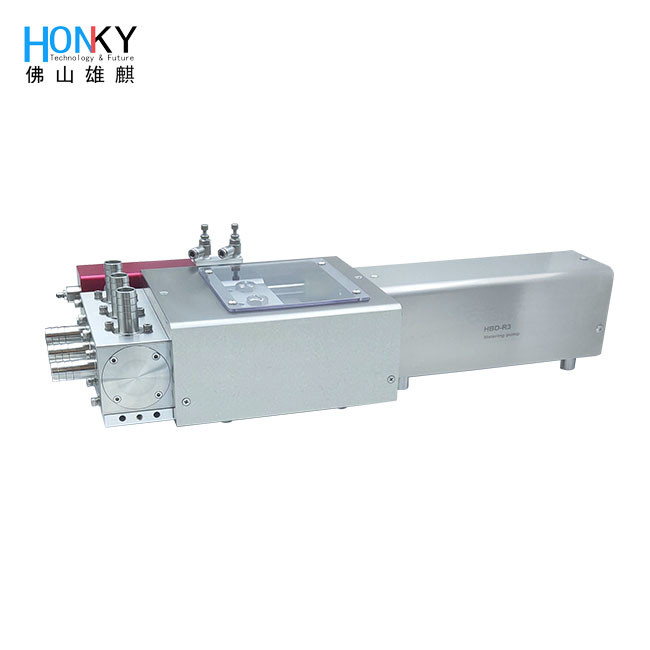

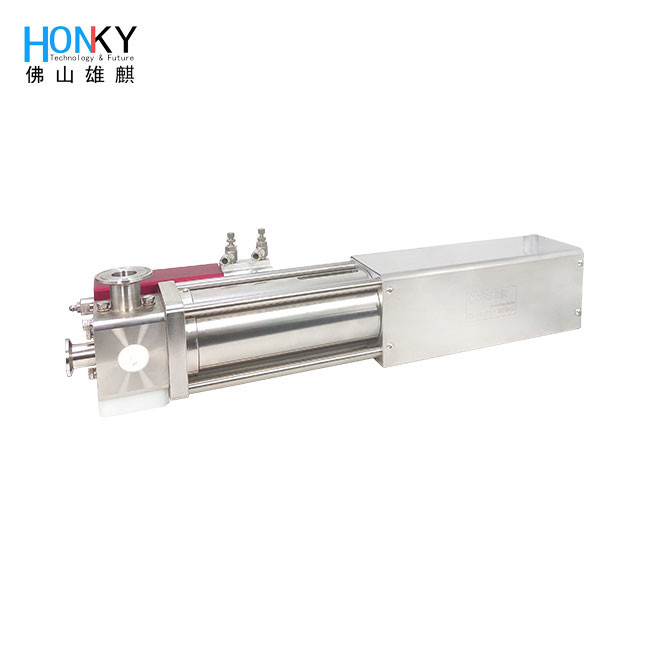

MMultiple Channel High Viscosity Cream Paste Electric Ceramic Filling Pump 30ml For Product Packing Machineultiple channel High Viscosity Cream Paste Electric Ceramic Filling Pump 30ml For Product Packing Machine

HBD-RN ceramic pneumatic pump integration adopts precision ceramic plunger design, suitable for medium and high viscosity liquids, homogeneous creams (1000-100,000CPS) and quantitative perfusion of materials containing certain particles. The pump has high metering accuracy and repeatability, with an accuracy better than ±0.8% to 1%. The metal part in contact with the material is made of 316L stainless steel, which has better corrosion resistance.

Industry application of Multiple channel High Viscosity Cream Paste Electric Ceramic Filling Pump

It can be used for supporting and transforming the filling part of the packaging machine. It is suitable for cream, honey, electrolyte, medicinal liquid, biochemical reagent, chemical liquid, essential oil, essence, lotion, perfume, nail polish and other medium and high viscosity homogeneous liquid materials. It can be used with multi-station bag packing machines, multi-row packaging machines, blister machines and other equipment.

Parameter of Multiple channel High Viscosity Cream Paste Electric Ceramic Filling Pump

|

Model

|

Plunger diameter(mm)

|

Stroke(mm)

|

Volume |

Accuracy

|

Speed |

| ml |

CPM |

| HBD-10R3 |

20 |

50 |

1-10 |

±0.5-1% |

30-45 |

| HBD-30R3 |

30 |

3-30 |

| HBD-50R3 |

38 |

5-50 |

Product display of Multiple channel High Viscosity Cream Paste Electric Ceramic Filling Pump

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

Advantage of our piston pump:

1.The working pressure, volumetric efficiency and total efficiency are all the highest. Because the plunger and cylinder bore are easy to process, the dimensional accuracy and surface quality can reach very high requirements, so the matching accuracy is high, the oil leakage is small, and the working pressure that can be achieved is generally 20-40 MPa, and the highest can reach 100 MPa.

2.The transmittable power is the largest. As long as the plunger diameter or the number of plungers is increased appropriately, the flow rate will increase. High pressure and high current can transmit high power.

3.Wide speed range.

4.Long service life and high power density. The main parts of the plunger pump are under pressure, so that the material strength can be fully utilized, so use long life, and low weight per unit power.

5.Good bidirectional variable capacity. Changing the stroke of the plunger can change the flow rate, making it easy to make various variable types.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!