High Purity Alumina Ceramic Filling Metering Double Head Pump Kits 0.05ML For Filling Machine UpgradingHigh Purity Alumina Ceramic Filling Metering Double Head Pump Kits 0.05ML For Filling Machine Upgrading

Characteristic of High Purity Alumina Ceramic Filling Metering Double Head Pump Kits

The X2-D Series Ceramic Pump Integration is a highly accurate and reliable precision metering pump designed for precise delivery of chemical liquids and high-purity fluids. Its operation relies on the rotary motion of a plunger, which, through an adjustable pump head angle, generates axial linear motion for accurate stroke control. This ensures a remarkable metering accuracy and repeatability of better than ±0.5%.

The pump stands out due to its:

Corrosion Resistance: Ceramic components resist chemical corrosion from acids, alkalis, salts, and other chemicals, making it suitable for handling corrosive liquids and enhancing equipment lifespan.

Wear Resistance: Ceramic plungers and valve seats are hard and wear-resistant, reducing the likelihood of wear or deformation over time.

Stability: The pump operates with low vibration and noise, ensuring smooth plunger movement and consistent flow rate and pressure stability.

Temperature Adaptability: Ceramic materials have a minimal thermal expansion coefficient, enabling the pump to function effectively in both high and low-temperature environments.

Leakage Prevention: The pump is well-sealed, preventing leaks and ensuring no contamination of the transported liquid. Additionally, ceramic materials are non-toxic, odorless, and non-polluting, preventing secondary pollution.

This pump is an ideal solution for applications where precision, durability, and chemical compatibility are crucial.

Application

The ceramic plunger pump can be used for conveying liquids with high viscosity, high temperature, corrosiveness, and prone to crystallization. Common applications include conveying, pressurizing, metering, and mixing processes in industries such as petrochemicals, food processing, and pharmaceutical manufacturing.

Technical data

| Item No. |

-03 |

-06 |

-09 |

-12 |

-15 |

-18 |

-21 |

-24 |

-27 |

| Pump material |

Ceramic parts: high purity alumina(Al2O3), zirconia(ZrO2), silicon carbide(SiC), etc. |

| Metal part: 316L stainless steel |

| Filling range |

4-80ul |

10-140ul |

20-240ul |

50-700ul |

0.2-1.5ml |

0.2-2.9ml |

0.6-6ml |

1-12ml |

2-25ml |

| Bore diameter |

φ4 |

φ5 |

φ7 |

φ10 |

φ13 |

φ15 |

φ22 |

φ25 |

φ36 |

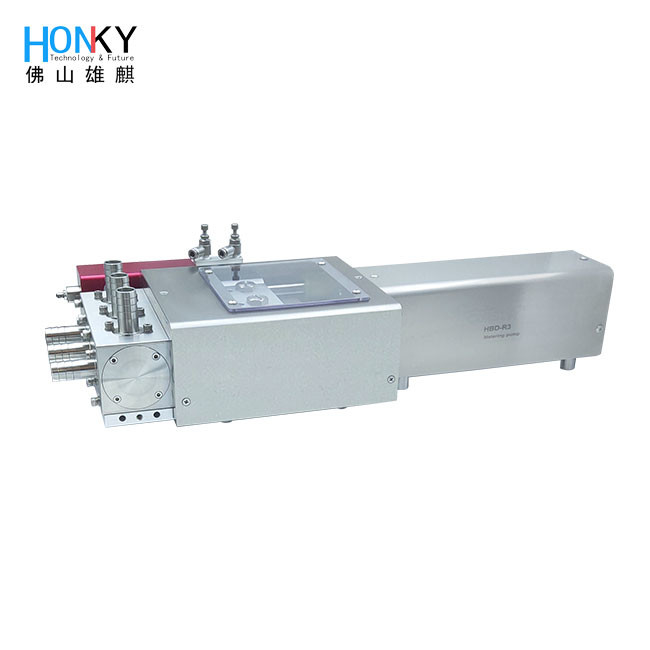

Product display

About HonkyTech

Foshan Xiongqi Intelligent Technology Co., Ltd(HONKY) is a leading manufacturer of all kinds of fluid filling solutions. The main products contain the ceramic pump, ceramic pump filling line series, ceramic pump spare parts or filling equipment, filling solution ODM, etc. Our products have a good reputation for quality, reliability, and efficiency.

Service of HonkyTech:

Pre-sales:

According to client requirements, supply reasonable mаsk machine sketch map, quotation and operation video for client ref first.

During Sales:

1) Depends on client objects, made reasonable reform based on the standard machine.

2) 24-hour uninterrupted test before machine delivery, make sure machine operation stable.

3) Execute SGS certification for the equipment and materials used in the production process requirement and specification strictly.

After-sale:

1. Provide complete teaching videos and materials, easy to operate and simple to maintain.

2. Experienced engineers provide online or computer guidance.

3. If in South Korea, we have a professional technical team that can provide door-to-door service.

4. Guarantees all equipment (except human factors) within one year, lifetime maintenance service.

5. After machine used for several years, SKILT promise to provide detailed refurbishment program, the original equipment and replacement of hardware and software upgrades, extending machine service life for more than 3-4 years.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!