Air Driven Type OEM Filling Machine Parts Ceramic Piston And Ceramic Rotary Valve With Customzing Size For Piston Pump

Parameter for Air Driven Type OEM Filling Machine Parts Ceramic Piston And Ceramic Rotary Valve

| Model |

XQQG-12 |

XQQG-25 |

XQQG-50 |

XQQG-100 |

| Pump head |

High purity ceramics |

| Filling accuracy |

±0.8% |

| Filling range |

1-12ml |

2-25ml |

5-50ml |

10-100ml |

| Manufacturing speed |

0-40 Bottle/min |

| Size of the pump |

Customizing |

| Power |

/ |

| Air pressure |

0.4-0.6Mpa |

The ceramic plunger pneumatic pump assembly adopts a precision ceramic plunger design, which is suitable for the quantitative infusion of medium and high viscosity liquids, creams, and creams (1000-100,000CPS) and materials containing certain particles.

Features for Air Driven Type OEM Filling Machine Parts Ceramic Piston And Ceramic Rotary Valve

The pump design incorporates a sophisticated tail screw fine adjustment structure, guaranteeing exceptionally high metering accuracy and repeat consistency. This precision mechanism surpasses the industry standard, achieving an accuracy better than ±0.5%, thereby ensuring reliable and consistent fluid metering across diverse applications.

The contact material's metal component is meticulously crafted from 316L stainless steel, a material highly esteemed for its exceptional corrosion resistance. This material choice not only bolsters the durability of the contact surface but also ensures resilience against harsh environments and chemicals, preserving its integrity and functionality over an extended period.

The pump body is ingeniously engineered with a quick-disassembly mode, significantly easing the processes of disassembly, assembly, and cleaning. This innovative design not only saves time and effort but also perfectly aligns with the stringent cleaning requirements outlined by food hygiene standards. By enabling easy access and thorough cleaning, it guarantees the pump's hygiene and compliance with the highest safety regulations in the food industry.

Industry application:

It can be used for the matching and transformation of the filling part of the packaging machine. It is very suitable for filling cream, honey, electrolyte, medicinal solution, biochemical reagent, chemical liquid, essential oil, essence, lotion, perfume, nail polish and other medium and high viscosity homogeneous liquid materials.

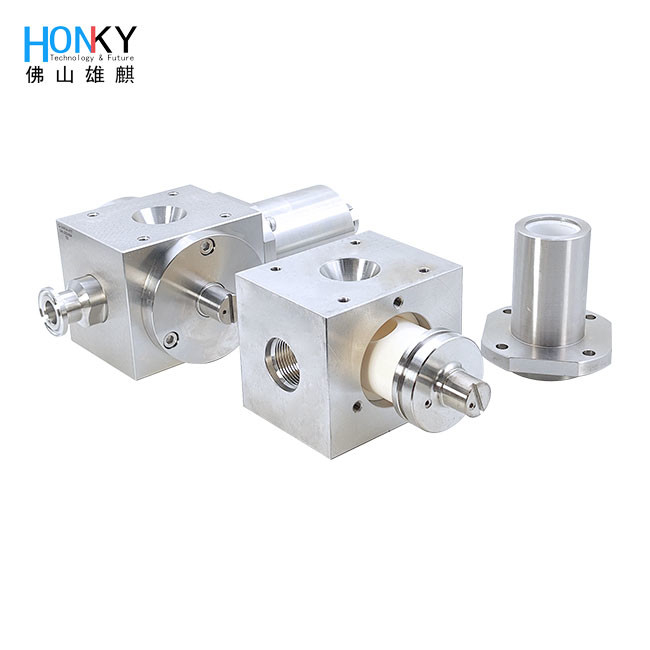

Product display for Air Driven Type OEM Filling Machine Parts Ceramic Piston And Ceramic Rotary Valve

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!