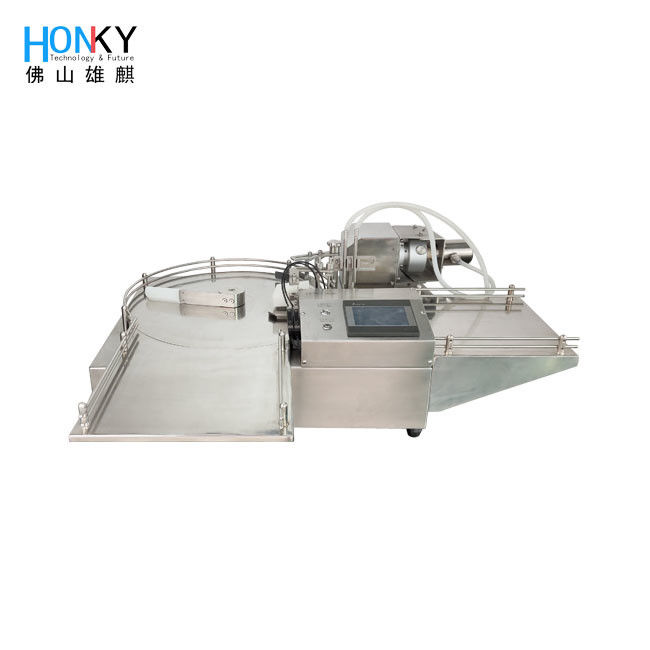

Desktop Round Bottle Filling Machine With Double Head Filling System For Oil Liuqid Essential Filling

Characteristic of Desktop Round Bottle Filling Machine:

This equipment has been tested to meet the requirements of GMP certification.

1. The system is designed to adopt a highly advanced and intelligent operating system. This state - of - the - art operating system is equipped with intuitive interfaces and smart algorithms, enabling users to easily manage and control various functions of the device. It can adapt to different working scenarios and user requirements, bringing a more efficient and convenient operation experience.

2. The liquid separation part of this device is specifically a high - purity ceramic pump. This type of pump is renowned for its excellent performance and durability. It precisely controls the amount of liquid injected in each cycle by carefully adjusting the angle of the pump head. This highly accurate control mechanism ensures that the liquid injection is consistent and meets the specific requirements of different production processes.

3. The equipment features an exterior made of 304 stainless steel, presenting a sleek and modern appearance. Its desktop structure is not only aesthetically pleasing but also highly practical and convenient. The desktop design allows for easy placement and operation, making it suitable for a variety of workbench setups. It can be easily integrated into different production environments without taking up excessive space.

4. This equipment is especially suitable for handling stable bottle shapes. The design of the equipment has been optimized to ensure seamless interaction with bottles that have consistent and stable shapes. It can accurately position and process these bottles, minimizing the risk of errors or inefficiencies during the production process. This makes it an ideal choice for industries that deal with a large number of stable - shaped bottles.

5. Changing bottle species with different diameters is both convenient and rapid. The equipment is equipped with an intelligent adjustment mechanism that can quickly adapt to various bottle diameters. Operators can easily make the necessary adjustments without the need for complex tools or long - drawn - out procedures. This flexibility allows for quick transitions between different production runs, enhancing overall production efficiency.

6. The device supports the Modbus 485 communication protocol. This widely - recognized communication protocol enables seamless integration with other devices and systems. It allows for efficient data transfer and communication, facilitating remote monitoring and control. With this support, the equipment can be easily incorporated into a larger network, enabling centralized management and optimization of the production process.

7. This equipment makes use of a German - made sensor to achieve the function of no filling without a bottle. The high - quality German sensor is highly sensitive and reliable. It can accurately detect the presence or absence of a bottle in the filling area. When no bottle is detected, the filling process is automatically suspended, preventing any waste of liquid and ensuring the integrity of the production process. This feature not only saves resources but also improves the overall quality control of the production line.

Technical parameters of Desktop Round Bottle Filling Machine:

| Model |

XQZPG-2B Double channel

|

| Pump head |

High purity ceramics |

| Filling accuracy |

≦±0.25% |

| Filling range |

0.5-2ml |

1.5-5ml |

3-10ml |

2-25ml |

|

| Bottle Diameter |

12-78mm |

| Manufacturing speed |

40-80 PCS/min |

| Size of Host Machine |

1130*430*240(mm) |

| Power |

AC 220V 50-60Hz 650W |

Product display of Desktop Round Bottle Filling Machine:

4000 BPH Desktop Essential Oil High Speed Filling Machine With Round Bottle Feeder For Cosmetic

Product diaplay: Totally desktop design to cut down the space cost and make the operation easily.

Automatic dual-channel bottle loading, multi-head filling. Suitable for a variety of standing stability products.

The machine is made of stainless steel 304. AndThe size of the machine can be customized according to the customer’s need.

The filling part adopts the precision ceramic pump developed independently, and the repeated accuracy can reach ±0.3%.

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!