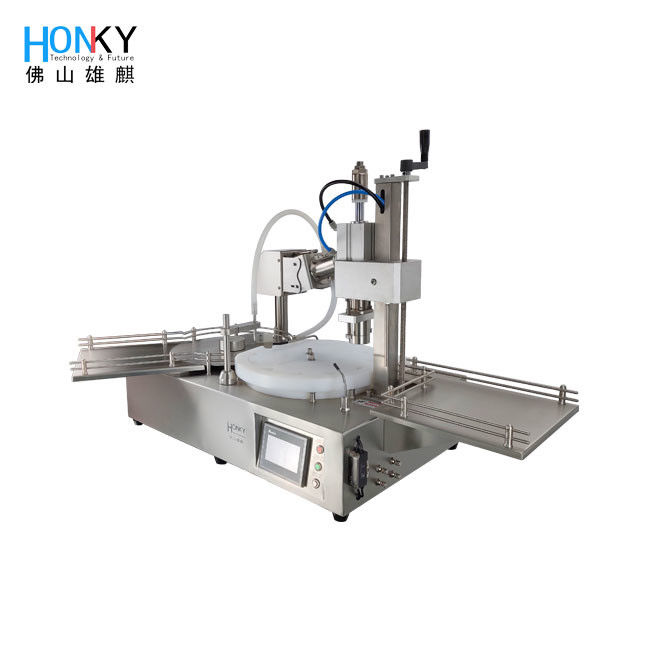

Desktop lab using 5ml vial filling and crimping machine with high filling precision for vial packing

Characteristic of Desktop lab using 5ml vial filling and crimping machine

The XQGM-30A is an innovative machine integrating filling and cap crimping functions. With an hourly efficiency of 1800 bottles, it's perfect for small-batch manufacturing, offering flexibility for various production runs. Its filling pump, the XQX2 series high purity ceramic pump, ensures extremely high measuring accuracy. It can precisely control the filling volume, maintaining consistency across bottles. This pump also has remarkable repeated consistency, reducing product waste even after long-term use.

The XQGM-30A uses a self-developed control system, optimizing performance and allowing easy parameter adjustment. Coupled with renowned brand air components known for reliability, the machine operates stably, minimizing breakdowns.

Moreover, this equipment has passed rigorous testing and meets GMP certification requirements. This certification validates its commitment to quality and compliance, enhancing its credibility in the manufacturing industry.

Technical data of Desktop lab using 5ml vial filling and crimping machine

| Model |

XQGM-30A |

| Filling range |

0.2-6ml |

1-12ml |

2-25ml |

|

| Filling accuracy |

≤0. 5% |

| sealing diameter |

φ13mm / φ15mm / φ20mm |

| Manufacturing speed |

12-22 PCS/min |

| Power |

AC 220V 50-60Hz 600W |

| Air pressure |

0.4-0.5Mpa |

| Size of Host Machine |

1230*780*600(mm) |

Product Display of Desktop lab using 5ml vial filling and crimping machine

This equipment has been tested to meet the requirements of GMP certification.

The separation part adopts high purity ceramic pump, which controls the injection volume of each lap by adjusting the angle of the pump head, and has extremely high measuring accuracy and repeated consistency.

Fully desktop design to make operation easily.

Advantages for using the ceramic pump:

1. Low Friction, Increased Packing Life

2. Extreme Wear Resistance

3. Increased Corrosion Resistance

4. Improved Anti-Galling Surface

Application area

1. ODM and OEM products design;

2. Automatic manufacturing line design;

3. Cosmetic product packing;

4. Pharmaceutical and bio-reagent product packing;

5. Laboratory Liquid dispensing;

6. Lithium Battery Liquid dispensing;

7. Ceramic pump and ceramic pump part design;

8. Other area's material filling;

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!