Desktop Clean Bench Using Vial Filling And Crimping Machine With Ceramic Piston Pump For Pharma Liquid Filling

Characteristic of Desktop Clean Bench Using Vial Filling And Crimping Machine

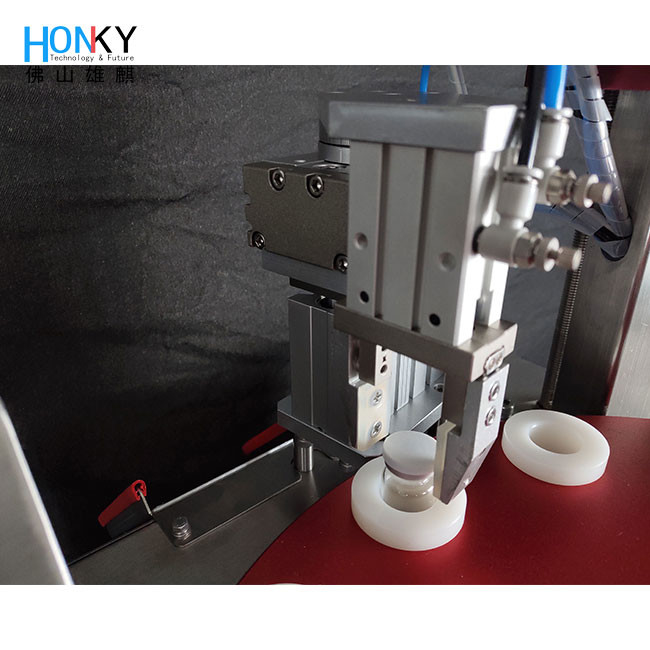

Our Desktop Clean Bench Integrated with Vial Filling and Crimping Machine is a compact, high-precision solution designed for pharmaceutical, biotechnology, and laboratory applications requiring sterile liquid filling and sealing. Equipped with a high-accuracy ceramic piston pump, this system ensures contamination-free, consistent dosing of sensitive liquids such as vaccines, injectables, and biologics.

Key Features:

✔ Ceramic Piston Pump – Superior chemical resistance, minimal wear, and ultra-precise filling volumes (adjustable from 0.1ml–100ml).

✔ All-in-One Functionality – Integrated filling + crimping (aluminum seal or cap) for seamless small-batch production.

✔ Touchscreen PLC Control – User-friendly interface for speed adjustment, fill volume calibration, and error diagnostics.

✔ Compact & Ergonomic Design – Space-saving desktop unit ideal for R&D labs, pilot batches, and low-volume manufacturing.

✔ Material Compatibility – Suitable for glass vials, ampoules, and pre-sterilized containers (customizable for different sizes).

Technical data of Desktop Clean Bench Using Vial Filling And Crimping Machine

| Model |

XQZGD-12C |

| Pump type |

Ceramic pump |

| Filling accuracy |

±0.5% |

| Filling range |

1-10ml |

| Manufacturing speed |

25-30 PCS / minute |

| Power |

AC 220V 50-60Hz 550W |

| Air pressure |

0.4-0.6Mpa |

| Machine size |

710*660*670mm (Main machine roughly) |

Product display of Desktop Clean Bench Using Vial Filling And Crimping Machine

2400BPH Plastic Ampoule Semi-Automatic Desktop Filling And Capping Machine With Ceramic Pump For Cosmetic

This equipment has been tested to meet the requirements of GMP certification.

The separation part adopts high purity ceramic pump, which controls the injection volume of each lap by adjusting the angle of the pump head, and has extremely high measuring accuracy and repeated consistency.

Fully desktop design to make operation easy.

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

About HonkyTech

Foshan Xiongqi Intelligent Technology Co., Ltd(HONKY) is a leading manufacturer of all kinds of fluid filling solutions. The main products contain the ceramic pump, ceramic pump filling line series, ceramic pump spare parts or filling equipment, filling solution ODM, etc. Our products have a good reputation for quality, reliability, and efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!