Desktop 1500 BPH 5ml Vial Filling Capping Machine Semi Automatic With High Precision Piston Pump For Essential Filling

Characteristic of Desktop Semi-Automatic 10ml Vial Filling And Capping Machine

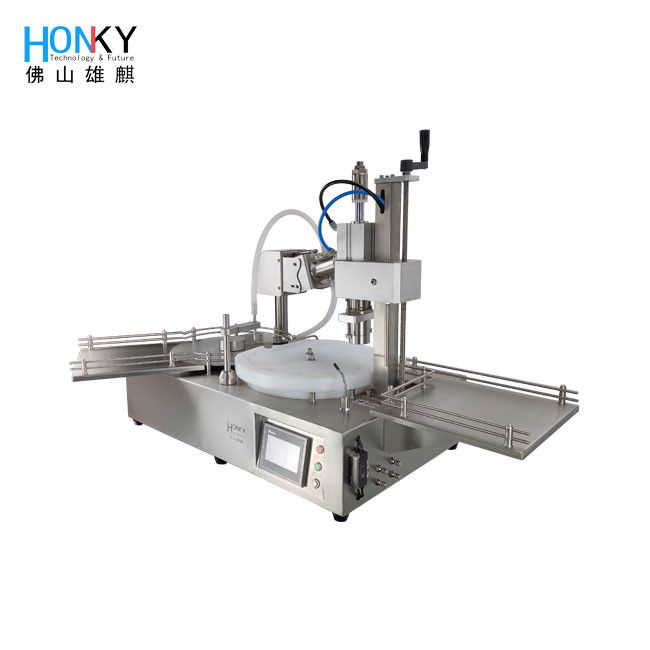

The XQGM-30A is a sophisticated and versatile machine designed to streamline the packaging process by seamlessly integrating the crucial functions of filling and cap crimping into a single, compact unit. Ideal for the pharmaceutical, food, and cosmetics industries, where precision and hygiene are paramount, this machine boasts an impressive capacity of processing up to 1800 bottles per hour, efficiently catering to the needs of small-scale manufacturers without compromising on productivity.

High-Precision Filling System

Equipped with the XQX2 series filling pump, the machine delivers exceptional dosing accuracy (≤±0.5%), ensuring minimal product waste and consistent fill volumes.

The high-purity ceramic pump is specifically designed for pharmaceutical applications, offering excellent chemical resistance and durability, making it suitable for handling sensitive liquids, including vaccines, injectables, and other sterile solutions.

Stable & Reliable Operation

The self-developed control system ensures smooth and precise operation, reducing downtime and enhancing productivity.

Premium-brand pneumatic components are integrated to guarantee long-term stability and minimize maintenance requirements.

Superior Crimping Performance

The high-quality crimp head ensures secure and consistent sealing, preventing leakage and maintaining product integrity.

The crimping mechanism is adjustable, allowing compatibility with various vial sizes and cap types.

GMP Compliance & Validation

The machine has undergone rigorous testing to meet GMP certification requirements, ensuring it adheres to the highest industry standards for pharmaceutical manufacturing.

Seamless Integration with Packaging Line

The XQGM-30A can be easily connected to a labeling machine, enabling a fully automated packaging process from filling to labeling, improving workflow efficiency.

Technical data of Desktop Semi-Automatic 10ml Vial Filling And Capping Machine

| Model |

XQGM-30A |

| Filling range |

0.2-6ml |

1-12ml |

2-25ml |

|

| Filling accuracy |

≤0. 5% |

| sealing diameter |

φ13mm / φ15mm / φ20mm |

| Manufacturing speed |

12-22 PCS/min |

| Power |

AC 220V 50-60Hz 600W |

| Air pressure |

0.4-0.5Mpa |

| Size of Host Machine |

1230*780*600(mm) |

Product display of Desktop Semi-Automatic 10ml Vial Filling And Capping Machine

1500BPH Vial Semi-Automatic Desktop Filling And Capping Machine With Ceramic Pump For Essential Oil

This equipment has been tested to meet the requirements of GMP certification.

The separation part adopts high purity ceramic pump, which controls the injection volume of each lap by adjusting the angle of the pump head, and has extremely high measuring accuracy and repeated consistency.

Fully desktop design to make operation easy.

Advantages for using the ceramic pump:

1. Low Friction, Increased Packing Life

2. Extreme Wear Resistance

3. Increased Corrosion Resistance

4. Improved Anti-Galling Surface

Why choose HonkyTech?

Rich Experience

There is skilled engineering staff with many years of experience, many of them have been engaging in this precision-filling industry for many years.

Quality Assurance

With a strict and effective quality control system, our products are CE approved, and we have ROHS Certificate.

In Stock

We keep stock of ceramic pump parts, electronic components, filling machine spare parts, etc. ready for immediate delivery.

Mature Technology

With numerous in-house service technicians and engineers, HONKY is ready to assist when you need technical support.

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!