Multiple Heads Servo Motor Driven High Precision Piston Pump With Mix Hopper For High Viscosity Material Quantative Packing

Parameter of Multiple Heads Servo Motor Driven High Precision Piston Pump

| Model |

XQQGS-12 |

XQQGS-25 |

XQQGS-50 |

XQQGS-100 |

| Pump head |

High purity ceramics |

| Filling accuracy |

≦±0.5% |

| Filling range |

1-12ml |

2-25ml |

5-50ml |

10-100ml |

| Manufacturing speed |

0-50 Bottle/min |

| Size of the pump |

50*15*15 cm |

| Power |

AC 220V 50-60Hz 50W |

| Air pressure |

0.4-0.6Mpa |

| Motor type |

Step motor/ servo motor |

The ceramic plunger pneumatic pump assembly adopts a precision ceramic plunger design, which is suitable for the quantitative infusion of medium and high viscosity liquids, creams, and creams (1000-100,000CPS) and materials containing certain particles.

Feature of Multiple Heads Servo Motor Driven High Precision Piston Pump:

1. Precision Metering with Full Automation

Engineered for unmatched accuracy, our pump integrates a fully automated adjustment system and a high-performance motor-driven mechanism, delivering industry-leading metering precision (±0.8%). Advanced servo control ensures consistent, repeatable dosing—ideal for pharmaceutical formulations, chemical processing, and food production. The automation reduces manual intervention, eliminating human error and boosting operational efficiency.

2. Superior Corrosion-Resistant Materials

Built to withstand harsh environments, all wetted metal components are crafted from 316L stainless steel, offering exceptional resistance to acids, alkalis, and saline solutions. Critical seals and wear parts feature high-purity ceramic for unmatched durability and chemical inertness. This robust material combination ensures long-term reliability in high-purity, sanitary, and aggressive chemical applications—guaranteeing contamination-free performance.

3. Quick-Disassembly Design for Easy Maintenance

Designed for hassle-free maintenance, the pump’s modular quick-disassembly structure enables tool-free dismantling, rapid cleaning, and compliance with FDA, EHEDG, 3-A, and GMP standards. Effortless access to internal components minimizes downtime and supports CIP/SIP processes—perfect for dairy, beverage, and biotech industries where hygiene and efficiency are critical.

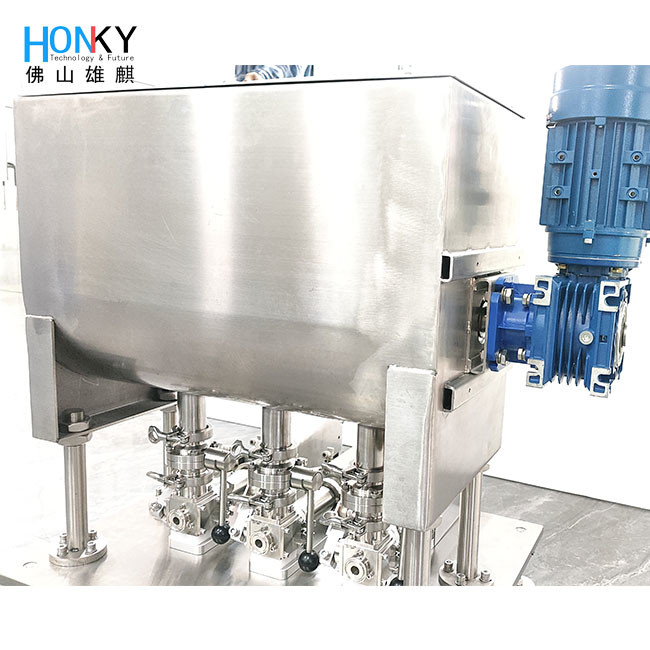

product display of Multiple Heads Servo Motor Driven High Precision Piston Pump:

Application area

1. ODM and OEM products design;

2. Automatic manufacturing line design;

3. Cosmetic product packing;

4. Pharmaceutical and bio-reagent product packing;

5. Laboratory Liquid dispensing;

6. Lithium Battery Liquid dispensing;

7. Ceramic pump and ceramic pump part design;

8. Other area's material filling;

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!