Desktop Semi-Automatic Frozen Dry Powder Liquid Filling and Capping Machine

This desktop semi-automatic machine with automatic capping system is specifically designed for cosmetic liquid packing applications, featuring high precision and hygienic construction.

Key Features

High-Precision Filling System

- Equipped with XQX2 high-precision ceramic pump for exceptional filling accuracy (±0.5% deviation)

- Wear-resistant and corrosion-resistant ceramic pump ensures long-term reliability

- Ideal for sensitive pharmaceutical formulations

Robust & Hygienic Construction

- Constructed from high-grade 304 stainless steel for superior durability

- Chemical resistant and compliant with GMP standards

- Smooth, polished surfaces facilitate easy cleaning and sterilization

High-Speed Production Capability

With a filling speed of up to 30 vials per minute, the XQXL-1C optimizes production throughput while maintaining precision for large-scale pharmaceutical manufacturing.

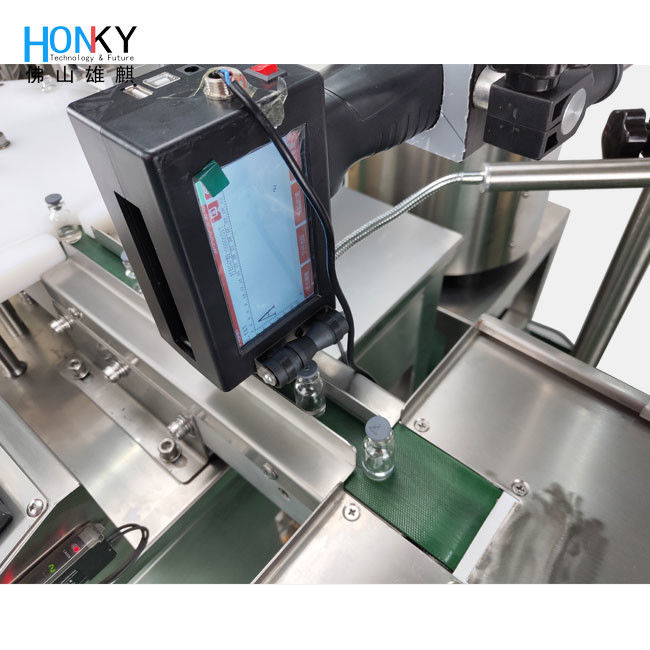

Integrated Traceability Function

Automatic code printing system enables batch numbering, expiration date marking, or QR code labeling for full product traceability and regulatory compliance.

Applications

Primarily designed for freeze-dried (lyophilized) powder pre-filling operations, widely used in vaccine production, biopharmaceuticals, diagnostic reagents, and injectable drug manufacturing.

Pharmaceutical Production Advantages

- Minimized human intervention reduces contamination risks in sterile environments

- Consistent dosage accuracy for high-value and sensitive drug formulations

- Seamless integration with lyophilization lines, capping systems, and downstream packaging equipment

Technical Specifications

| Model |

XQXL-1C |

| Pump Type |

Ceramic Pump |

| Filling Accuracy |

±0.5% |

| Filling Range |

0.6-6ml |

| Manufacturing Speed |

25-30 PCS / minute |

| Power |

AC 220V 50-60Hz 550W |

| Air Pressure |

0.4-0.6Mpa |

| Machine Size |

1500*850*750mm (Main machine roughly) |

Product Display

This equipment has been tested to meet the requirements of GMP certification.

The separation part adopts high purity ceramic pump, which controls the injection volume of each lap by adjusting the angle of the pump head, and has extremely high measuring accuracy and repeated consistency.

Fully desktop design to make operation easy and with the date printing function.

About HonkyTech

Foshan Xiongqi Intelligent Technology Co., Ltd (HONKY) is a leading manufacturer of all kinds of fluid filling solutions. The main products contain the ceramic pump, ceramic pump filling line series, ceramic pump spare parts or filling equipment, filling solution ODM, etc. Our products have a good reputation for quality, reliability, and efficiency.

Our Capabilities

Partnership

Dedication to co-operate in a spirit of partnership, trust and loyalty to achieve jointly defined objectives.

Geographical Coverage

Adequate coverage of the territory, ensuring efficient distribution of products to final industrial end users.

Warehouse & Equipment

State of the art logistic equipment for storage, handling, diluting, packaging, etc., meeting strict safety and environmental standards.

Sales Force

Efficient sales team, sufficiently staffed and well trained, to offer industrial end-users the best solutions.

Product Range

Quick understanding of product range based on educational and practical experiences.

Market Intelligence

Intimate understanding of specific market segments to serve end users with the best products.

Financial Stability

Solid financial situation allowing consolidation and development of our common relationship.

Technical Competencies

Unparalleled support in technical, commercial and market relationships to build business for our customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!