High-Precision Ceramic Filling Pump for Corrosive Liquids (Acids/Alkalis) – 1-10ml Adjustable Flow

The rotary ceramic plunger pump assembly is a plunger precision metering pump designed for metering, transporting, or quantitatively filling chemical liquids and high purity liquids. Through adjustable pump head angle, it generates axial linear motion during plunger rotation, enabling precise stroke adjustment for controlled input and output.

Key Features

- High-Quality 316 Stainless Steel Construction: All liquid-contact metal parts are made from 316 stainless steel for superior corrosion resistance, making it ideal for pharmaceutical and chemical industries. The pump maintains liquid purity without generating trace impurities.

- Removable Plunger Assembly: Easy-to-clean design reduces downtime and extends service life.

- Exceptional Metering Accuracy: Delivers precision with error margin better than ±0.05% (five-thousandths), critical for laboratory reagent dosing and pharmaceutical formulations.

- X2 Series Design: Simple, reliable structure with low learning curve, suitable for diverse applications from labs to production lines.

Industry Applications

Ideal for packaging machine integration and filling applications including electrolytes, medicinal liquids, biochemical reagents, chemical liquids, essential oils, emulsions, perfumes, and other medium-low viscosity homogeneous liquids.

Technical Specifications

| Item No. |

-03 |

-06 |

-09 |

-12 |

-15 |

-18 |

-21 |

-24 |

-27 |

| Pump Material |

Ceramic parts: high purity alumina (Al2O3), zirconia (ZrO2), silicon carbide (SiC), etc.

Metal part: 316L stainless steel |

| Filling Range |

4-80ul |

10-140ul |

20-240ul |

50-700ul |

0.2-1.5ml |

0.2-2.9ml |

0.6-6ml |

1-12ml |

2-25ml |

| Bore Diameter |

φ4 |

φ5 |

φ7 |

φ10 |

φ13 |

φ15 |

φ22 |

φ25 |

φ36 |

| Motor RPM |

400 | 350 | 300 | 250 | 200 |

|

| Accuracy |

Better than ±0.5% |

| Power Supply |

AC 220V 50/60Hz (110V optional) |

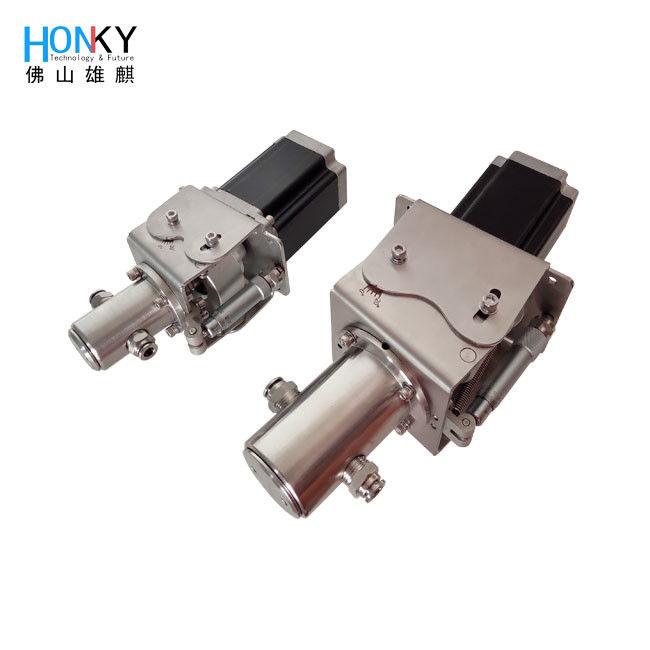

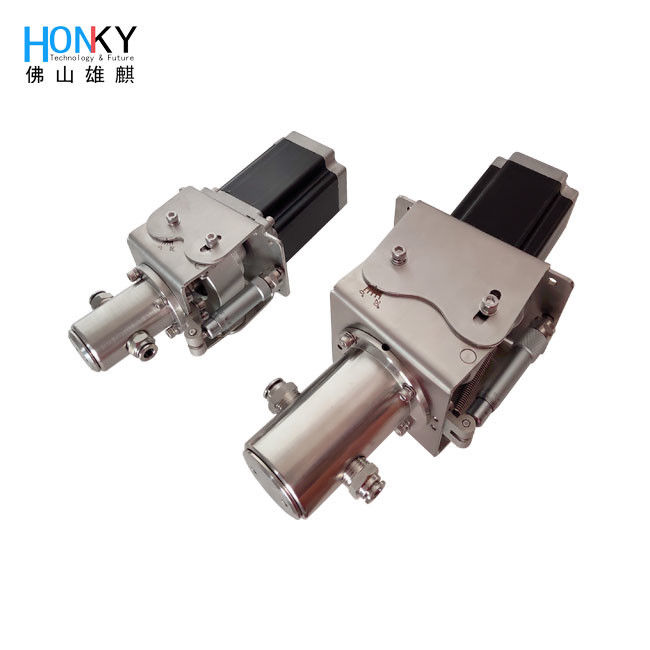

Product Images

Application Areas

- ODM and OEM products design

- Automatic manufacturing line design

- Cosmetic product packaging

- Pharmaceutical and bio-reagent product packaging

- Laboratory liquid dispensing

- Lithium battery liquid dispensing

- Ceramic pump and parts design

- Other material filling applications

Frequently Asked Questions

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we offer both OEM services and technical support for international distributors.

Q: How about the after-sales service?

A: The machine comes with a 1-year warranty and lifetime after-sale service with technical support.

Q: What are your Installation Services?

A: We provide comprehensive installation support including user manuals, instructional videos, and guidance for machine setup, debugging, and operation.

Q: What info will be needed to confirm machine models?

A: Please provide: 1) Material status, 2) Filling range requirements, 3) Manufacturing speed needs, 4) Any specific production process requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!